Discover SmartPixels’ top-notch 3D scanning services

Whether your 3D studio is overbooked, you are lacking resources or you are simply not ready to invest in multiple costly 3D scanners, SmartPixels have got you covered!

Our cutting-edge technology and expert team ensure precise and accurate 3D scanning services, allowing you to capture detailed rough 3D models. Our team of seasoned professionals, backed by extensive industry experience, is poised to ensure the success of your upcoming digitization endeavour.

Why should brands scan their products in 3D?

Harness the power of 3D scans to unlock a multitude of advantages, including:

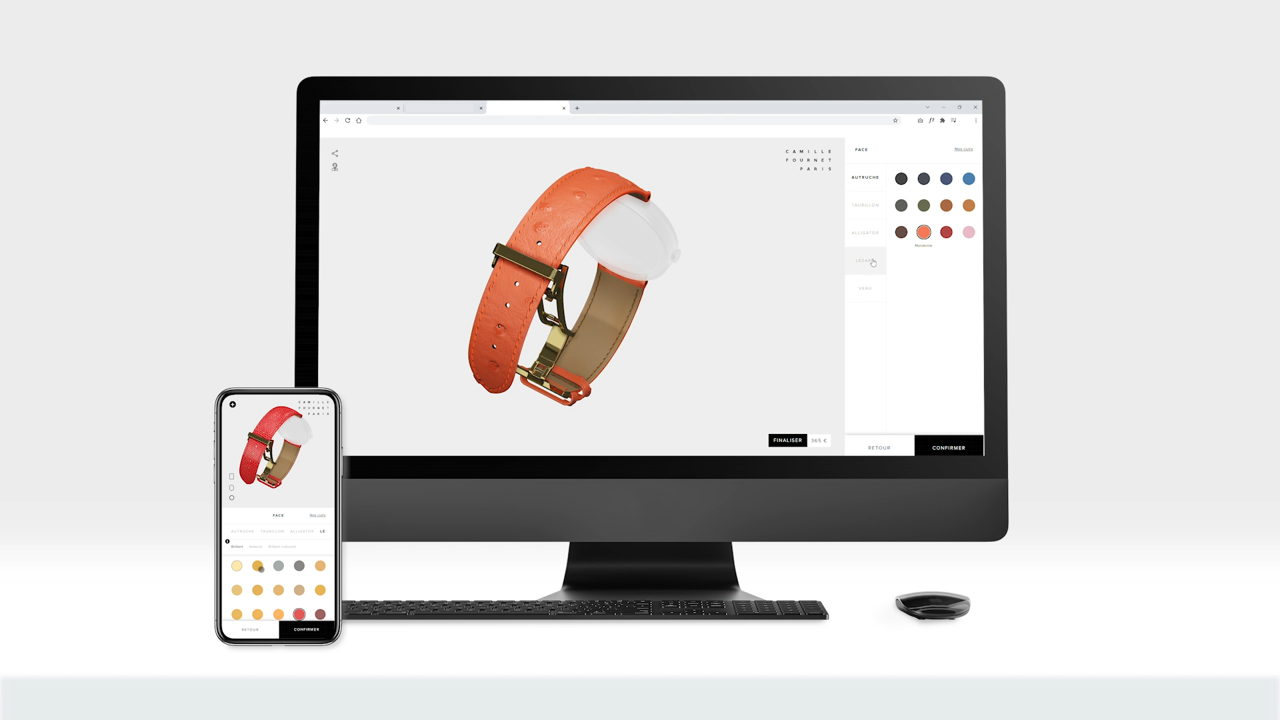

Interactive 3D Product Visualizations

With 3D scans, you can present your products in an immersive and engaging way, allowing customers to explore every angle, zoom in, and interact with the 3D Digital Twin. This enhances their understanding of your products and boosts their confidence in making a purchase.

Interactive 3D Product Personalization

Leveraging 3D scans, you can offer personalized and tailor-made products. By capturing precise measurements and details of individual customers, you can create customized products that perfectly fits their needs and preferences. This level of personalization enhances customer loyalty and drives repeat purchases.

Augmented Reality Experiences

By utilizing 3D scans, you can enable customers to visualize products in their environment at the right scale, to virtually try on clothing, accessories, or even cosmetics. They can see how the items look on themselves or in their environment, increasing convenience and customer satisfaction.

Incorporating 3D scans into your workflow empowers your business with visually stunning, interactive experiences, and opens up new avenues for customer engagement, satisfaction, and sales growth.

Benefits of SmartPixels 3D Scanning Services

At SmartPixels, our focus is on delivering high-quality 3D scans, prioritizing accuracy, and precision in capturing the subject. Here’s how we ensure top-notch results:

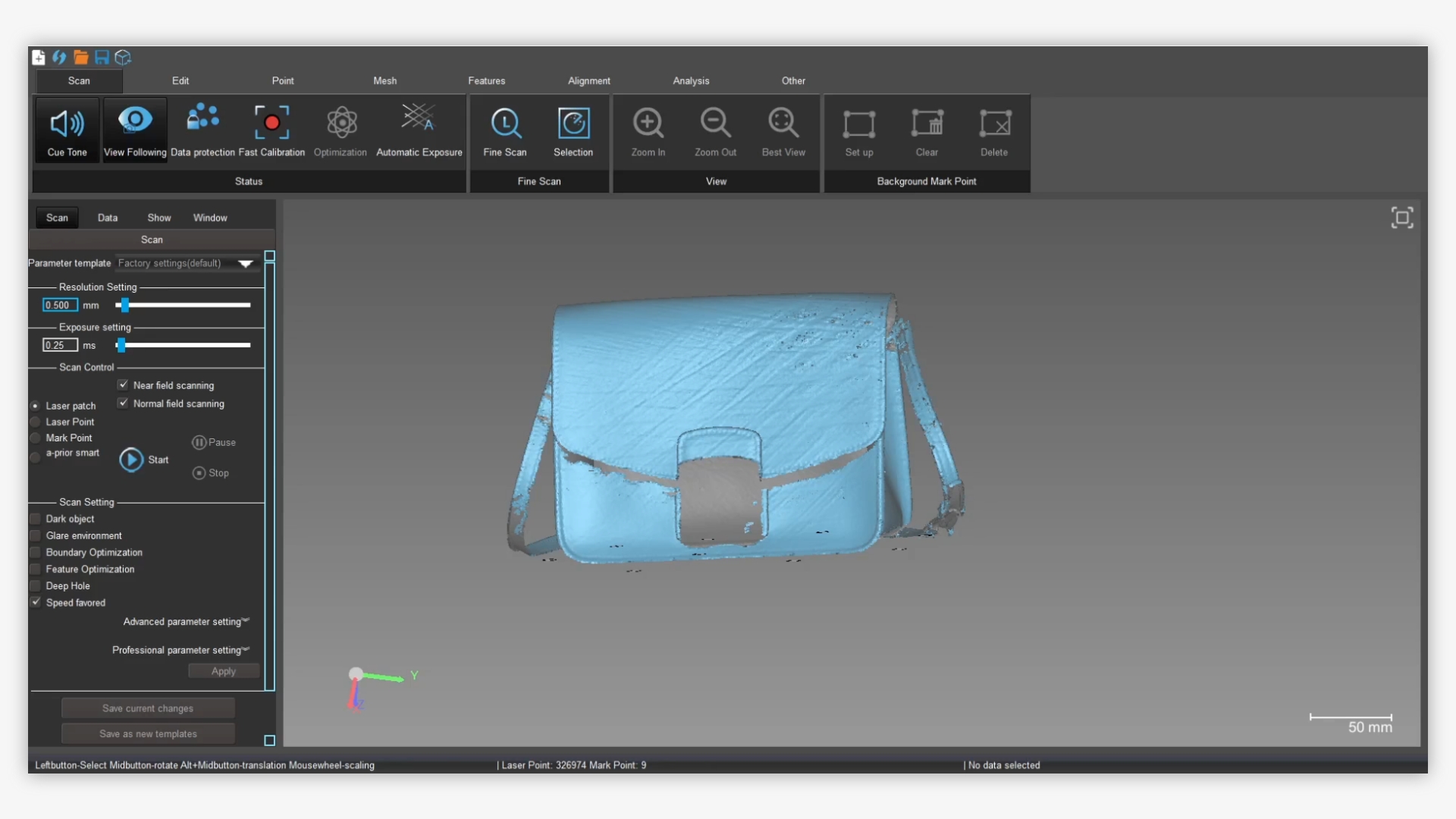

High-Quality 3D laser scans

We employ state-of-the-art 3D laser scanning devices capable of capturing intricate details with exceptional precision. These high-resolution laser 3D scanners ensure that every element of your subject is captured accurately, leaving no room for compromise in the final output.

Experienced 3D scanning service team

Our team of skilled 3D artist are well-versed in operating the 3D laser scanning equipment and optimizing the 3D scanning process.

They utilize advanced data processing techniques to meticulously process the captured 3D scans. Through meticulous cleanup, reconstruction, and refinement processes, we ensure that the resulting data is of the highest quality, ready for use in various applications.

Tailored 3D scanning services

With years of experience in the fashion and luxury industry, our team understands the specific needs of different types of products (leather goods, shoes, luggage…), tailoring our 3D scanning services to meet your requirements.

We offer flexible 3D scanning services, allowing you to choose the level of detail, resolution, and format that best suits your project needs.

Time and cost efficiency

We implement rigorous quality control measures to guarantee the accuracy and consistency of our outputs. Our experienced professionals meticulously review and verify the scanned data, ensuring it meets the required standards and matches your specific project requirements.

By leveraging our experience in the 3D field and our efficient processes, we provide quick turnaround times without compromising on the quality of the 3D laser scans, saving you time and resources.

Confidentiality and security

We prioritize the security and confidentiality of your data, ensuring that your 3D scans and sensitive information remain protected.

By combining state-of-the-art equipment, advanced data processing techniques, and meticulous quality control, we guarantee that the results we deliver are accurate, reliable, and optimized for your specific needs.

While retopology is not performed at this stage, our focus is on capturing accurate and detailed raw 3D scan data, providing a solid foundation for subsequent stages of the 3D modeling pipeline.

Our customers say it best!

The process: How SmartPixels 3D scan an object step by step?

When 3D scanning a product with SmartPixels using a laser scan, the following general process is typically followed:

Step 1: Preparation & Setup

The product to be 3D scanned is prepared by ensuring it is clean and free from any debris or dirt that could affect the scan quality. We start with meticulous preparation, strategically placing markers as reference points on the platform and product. The object is positioned precisely, capturing its desired form and orientation. Any reflective or shiny surfaces may require a special coating or markers to aid in the scanning process.

The scanning equipment is set up in a controlled environment to minimize external factors that could impact the scan quality. This includes controlling lighting conditions, reducing vibrations, and positioning the subject appropriately.

Step 2: 3D Scanning

The laser scanning process begins, where the laser scanner emits a laser beam that sweeps across the product's surface. The 3D scanner, equipped with multiple lasers and cameras, measures the time it takes for the laser to bounce back, capturing precise distance and geometric information immediately visible. Multiple scans are typically performed from various angles to capture a comprehensive view of the product.

The final scans faithfully represent the object, capturing intricate details like engravings and embossments, producing a detailed point cloud.

Step 3: Data Processing

Through a precise fusion of multiple scans, we create a unified scan for each product. Once the scans are complete, the captured data is processed using advanced data processing techniques. This involves cleanup, alignment, and refinement processes to enhance the quality and accuracy of the scan data. Noise reduction algorithms may be applied to remove any unwanted artefacts or imperfections.

Step 4: Quality Control

The processed scan data is rigorously reviewed and checked for any misalignments, inconsistencies, or errors. This ensures that the final scan data meets the required quality standards and accurately represents the product.

Step 5: Final Output

The high-quality scan data is then delivered to the client in a suitable format, such as a 3D point cloud or a high-quality mesh file that can be exported in OBJ or STL format, ready for further use in various applications. It can be utilized for 3D visualization, virtual reality, augmented reality, product design, or any other desired application.